Vacuum Packaging Machine Full Automatic Line IL 2024

Fully Automatic Vacuum Packaging Solution for High Efficiency

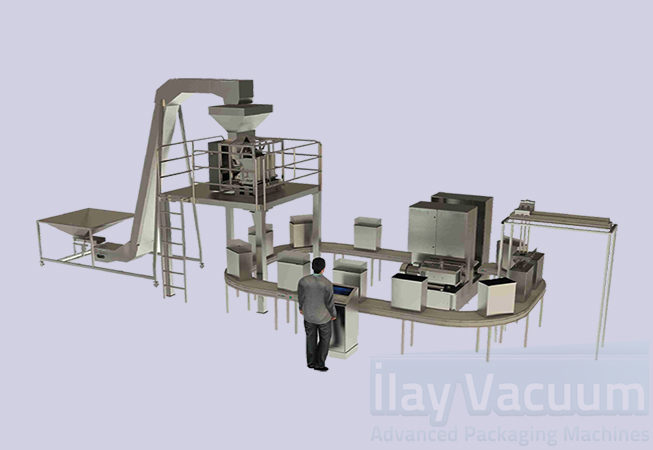

The Vacuum Packaging Machine Full Automatic Line IL 2024 is an advanced, patent-protected packaging system designed for high-capacity vacuum packaging. This fully automated line efficiently processes a variety of agricultural products, nuts, grains, and coffee, ensuring seamless packaging operations without requiring operator intervention.

High-Capacity Vacuum Packaging for Various Products

The IL 2024 model is engineered to handle 5 kg to 50 kg of various food products, including:

- Pinto beans, chickpeas, and other agricultural crops

- Walnuts, hazelnuts, peanuts, macadamia nuts, pecans, and shell nuts

- Wheat, white flour, and various spices

- Coffee beans, cashews, and almonds

With the ability to vacuum pack 3-6 tons per hour, this system significantly improves efficiency in food packaging operations.

Advanced Automation with PLC-Controlled System

Integrated System Components

The Vacuum Packaging Machine Full Automatic Line IL 2024 consists of:

- Transferring robot – Ensures smooth and precise product movement

- Elevator system – Automatically lifts products to the filling unit

- Conveyors – Customizable for seamless integration into existing production lines

- Filling unit – Precisely measures and dispenses products into packaging

- Automatic vacuum machine – Seals and vacuum-packs products efficiently

Customizable and Modular Design

All components are controlled by advanced PLC software, allowing full synchronization and automation. The system can be easily adapted and customized based on:

- Production speed and volume

- Factory layout and existing equipment

- Specific packaging requirements

The modular design ensures easy integration with previously installed conveyor systems, making it a flexible solution for growing production facilities.

Compliance and Cost Efficiency

Certified for Safety and Food Standards

The IL 2024 automatic vacuum packaging machine meets international CE conformity and food safety regulations. It ensures hygienic and contamination-free packaging, maintaining product freshness and extending shelf life.

Significant Cost and Time Savings

By automating the packaging process, the IL 2024 model reduces:

- Labor costs – No need for constant operator supervision

- Energy consumption – Optimized power usage for cost-effective operation

- Time spent on packaging – Increased speed and accuracy

- Transfer and transportation expenses – Efficiently packed products reduce logistics costs

How the IL 2024 Model Enhances Production Efficiency

Seamless Integration with Existing Systems

The IL 2024 model is designed to work in sync with existing production lines. Whether integrating into a newly established facility or upgrading an older system, this machine seamlessly connects with modular conveyor belts, robotic arms, and automated filling systems. This feature allows businesses to scale up their production without major overhauls or disruptions.

User-Friendly Operation and Maintenance

Despite its high level of automation, the IL 2024 model is designed with ease of use in mind. The touchscreen PLC interface provides an intuitive and accessible way to monitor and control the entire system. Operators can easily adjust packaging parameters, monitor performance, and troubleshoot issues with minimal training.

The machine also features low-maintenance components that minimize downtime and increase overall operational efficiency. The durable construction ensures long-term reliability, making it a cost-effective investment for businesses.

Versatile Applications for Different Industries

The Vacuum Packaging Machine Full Automatic Line IL 2024 is not limited to just food packaging. It can also be used in:

- Agriculture – Packaging grains, seeds, and other bulk products

- Nut Processing – Vacuum-sealing walnuts, almonds, peanuts, and more

- Coffee Industry – Ensuring airtight coffee packaging to preserve freshness

- Flour and Spice Production – Extending shelf life by preventing contamination

This adaptability makes the IL 2024 model an ideal choice for a wide range of industries that require high-volume vacuum packaging.

Why Choose the IL 2024 Full Automatic Vacuum Packaging Line?

The Vacuum Packaging Machine Full Automatic Line IL 2024 is the ultimate solution for businesses seeking to enhance efficiency, automation, and cost-effectiveness in vacuum packaging. With its high-speed operation, precision engineering, and compliance with food safety standards, it is the ideal choice for large-scale food packaging industries.

Key Benefits of the IL 2024 Model

- High-speed vacuum packaging (3-6 tons per hour)

- Advanced PLC-controlled automation

- Fully customizable to meet business needs

- Reduces operational costs and labor expenses

- Certified for food safety and CE compliance

- Durable, low-maintenance design

For more information about customization options and installation support, contact us today!

automatic vacuum packaging machine, vacuum packaging machines, fully automatic vacuum packing machine

Customization requests for different sizes are welcome.